Seco 1.60 sawir leh Lens Shmc

Cayimid

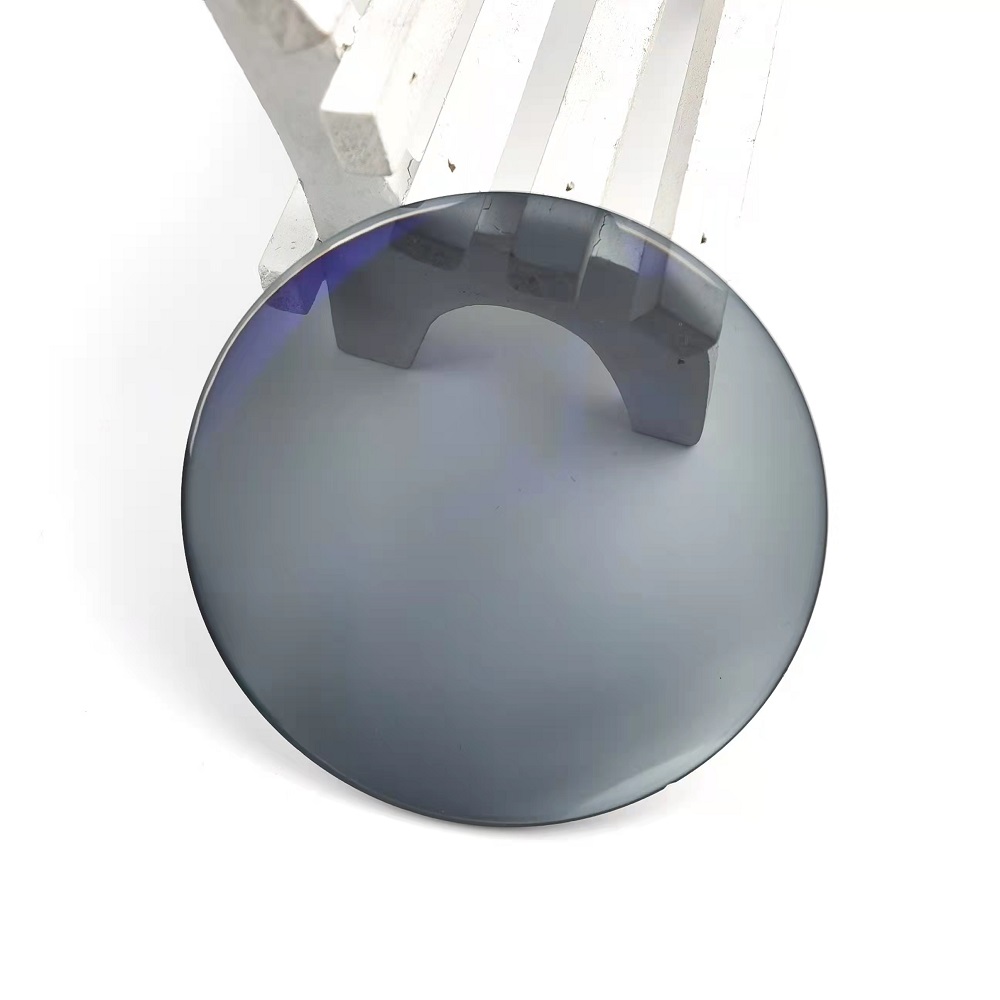

| 1.60 Sawir gacmeedka Shmcromic Shmc Evithical lens | |

| Moodel: | 1.60 Lind Optical |

| Meesha asalka ah: | Jiangsu, Shiinaha |

| Nooc: | Isku dejin |

| Qalabka muraayadaha indhaha: | Harin |

| Midabka muraayadaha indhaha: | Waadixin ah |

| Tusmada Fikradda ah: | 1.60 |

| Dhexroor: | 75/70/65 mm |

| Hawsha: | sawir maalmam |

| ABBE qiimaha: | 32 |

| Xirfad gaar ah: | 1.26 |

| Xulashada Daynta: | HMC / SHMC |

| Midab dahaad | Cagaar |

| TILMAAMAHA: | SPH: 0.00 ~ -10.00; +0.25 +6.00; Cyl: 0.00 ~ -4.00 |

Astaamaha wax soo saarka

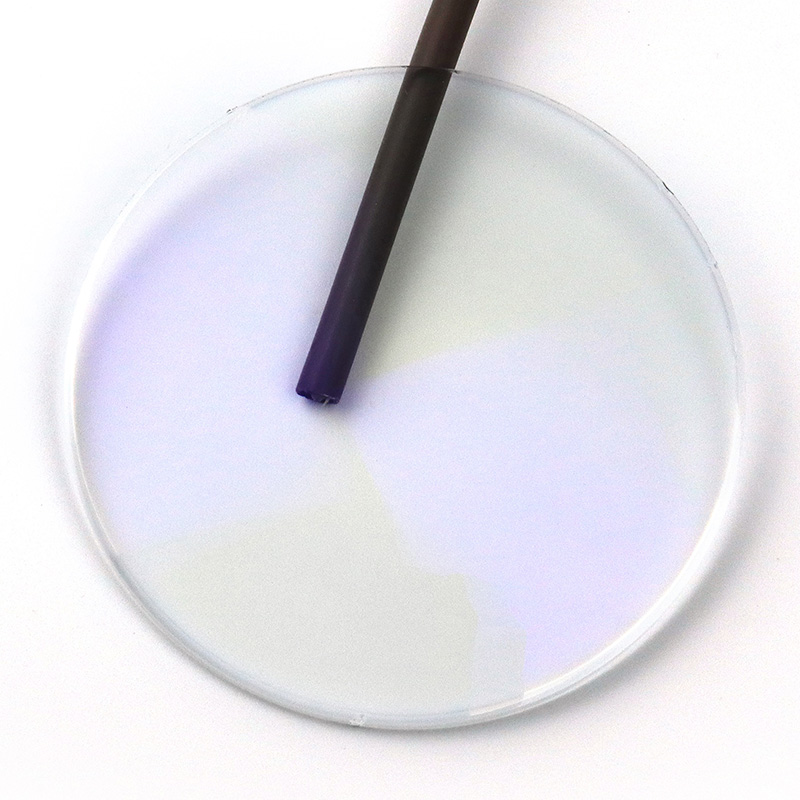

1) Waa maxay daboolka laf-dhabarka?

Qeyb daboolan waa hab loo isticmaalo in lagu keydiyo filimada khafiifka ah ee isku-dhafka ah ee ku yaal meelaha banaan. Badanaa qadar yar oo ka mid ah waxyaabaha daboolka lagu dabaqayo waxaa lagu dabaqayaa bartamaha substrate, oo ah laf-dhabarta xawaaraha hoose ama haba yaraatee. Substrate-ka ayaa markaa loo wareejiyaa xawaaraha illaa 10,000 rpm si ay ugu faafiyaan qalabka daboolka ee xoogga Centrifugal. Mashiin loo isticmaalo dahaarka laf-dhabarka waxaa lagu magacaabaa xijaab, ama si fudud lafdhabarta.

Wareegga ayaa sii socda inta dareeraha ah uu ka soo baxo cidhifyada substrate-ka, ilaa dhumucda la rabay ee filimka lagu guuleysto. Qalinka lagu dabaqay ayaa badanaa kacsan, isla mar ahaantaana wuu ka baxayaa. Xawaaraha sare ee xawaashka ah ee kudhaca, filimka khafiifka ah. Dhumucda filimka ayaa sidoo kale kuxiran cod-galka iyo fiirsashada xalka, iyo dareeraha. [2] Falanqaynta fikradda ah ee loo yaqaan 'Pioneecication' [5] Ayaa helay sharaxaad guud oo lagu saadaalinayo dhumucda filimka dhigata).

Daboolida lafdhabarta ayaa si ballaaran loogu isticmaalaa microfabilation ee lakabyada oxide-ka ee shaqeynta ah ee ku yaal dhalada ama hal qaybood oo isku-dhafan, halkaas oo loo isticmaali karo in lagu abuuro filimyo yar yar oo khafiif ah oo leh dhumucdii nanoscale. [6] Waxaa si xoogan loogu isticmaalaa Photolitrofitraphy, si loo dhigo lakabyada sawir-qaadista qiyaastii 1 micrometre qaro weyn. Sawir-gacmeedka ayaa sida caadiga ah ku garaacaya 20 ilaa 80 kacdoon halkii ilbidhiqsi 30 ilaa 60 sekan. Waxaa sidoo kale si weyn loogu isticmaalaa xarkaha qaabdhismeedka sawir qaade ee diyaaradda ka samaysan polymers.

Hal faa iido ah oo ah filimaanta khafiifka ah ee wareejinta ayaa ah isku xirnaanta dhumucda filimka. Adigoo u dhigma is-dhexgalka, dhumucduhu wax ka badan 1%. Si kastaba ha noqotee, filimada qarka udhaca ee polymers ee pomoomers iyo sawir-gacmeedyadu waxay ku dambayn karaan ganaax weyn oo geeska ah oo ay ku jiraan meelahooda jirka.

2) Sidee ayey u shaqaysaa shaqada dahaarka ah?

Hawshani waxay si taxaddar leh u xakameysaa xawaaraha la xiriira xadka qaraabada guryaha kala duwan ee xalka. Viscosity waa Prime Rifel-ka ee ku dhex jira guryahaas maadaama ay go'aamiso iska caabbinta qulqulka labiska, taas oo muhiim u ah gaarista dusha isku-dhafka ah. Daboolida lafdhabarta ayaa markii dambe lagu fuliyaa guud ahaan xawaaraha xawaaraha, in ka yar 500 kacdoon daqiiqaddii (rpm) illaa iyo inta ugu badan 12,000 rpm - iyadoo kuxiran viscosity xalka.

Viscosity ma aha in hantida kaliya ee xiisaha leh ee iskuxirka lafdhabarta, hase yeeshe. Xiisadda dusha sare ayaa sidoo kale saameyn ku yeelan karta astaamaha qulqulka xalka, halka boqolkiiba ay culuhu ay saameyn ku yeelan karaan dhumucda qafiifka ah ee khafiifka ah ee loo baahan yahay si loo gaaro astaamaha ugu gaarka ah ee loo adeegsado (tusaale ahaan dhaqdhaqaaqa korantada). Daboolida lafdhabarta ayaa markaas lagu sameeyaa faham buuxa oo ku saabsan astaamaha ay quseyso, oo leh cabirro badan oo la isku hagaajin karo si ay ugu habboon yihiin astaamaha kala duwan (qulqulka, viscolity, iwm.).

Daboolida lafdhabarta ayaa lagu samayn karaa iyadoo la adeegsanayo bilow wanaagsan ama firfircoon, mid kasta oo loo diyaarin karo dardargelinta isticmaale-qeexida ee loo yaqaan 'Usping' iyo xawaaraha kaladuwan ee kaladuwan. Waxa kale oo muhiim ah in la oggolaado muddada haradka ah iyo waqtiyada qalajinta maadaama hawo liidata ay ku dambayn karto cilado indhaha ah iyo mid aan isku xirnayn. Tusaale ahaan: Qaab-dhismeedka SWiast-ka ayaa laga yaabaa inay muujiso in heerka qiiqa uu aad ugu sarreeyo xalka qaadanaya waqti dheer in la qalajiyo. Ma jiro hal-cabir-ku habboon - dhammaan xalka marka ay timaado dahaarka lafdhabarta, iyo geeddi-socod kasta waa in lagu fuliyaa qaab guud oo ku saabsan xalka hoose ee sunta ah ee su'aasha.

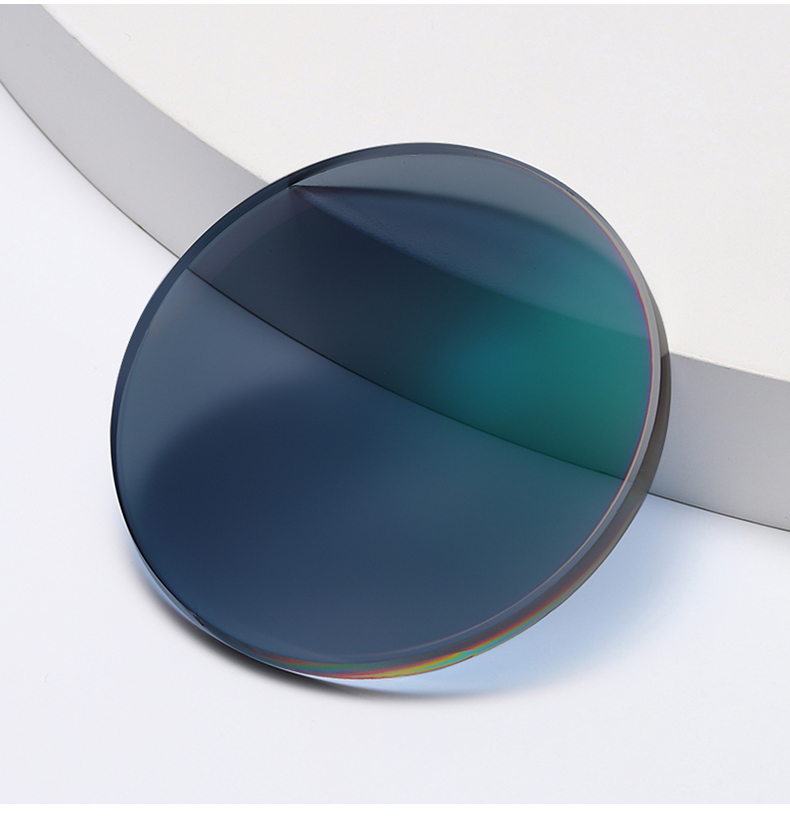

3) Xulashada Daynta?

Maaddaama 1.60 Photochromic lens shmc, super hydrophobic dahaadhu waa doorashada kaliya ee darada ee ay u leedahay.

Daboolida super hydrophobic wuxuu sidoo kale magacaabi karaa daaha Crazil, wuxuu ka dhigi karaa muraayadaha biyaha, tamarta ka hortagga, ka hortagga, la-dagaallanka la-dagaallanka iyo iska caabbinta saliida.

Guud ahaan marka la hadlayo, daboolka super hydrophobic wuxuu jiri karaa 6 ~ 12 bilood.

Shahaado

Warshadeena